Home | Injection Mold

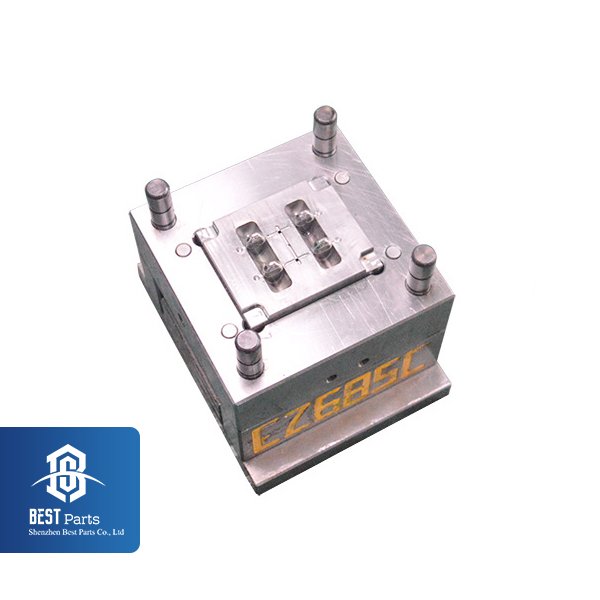

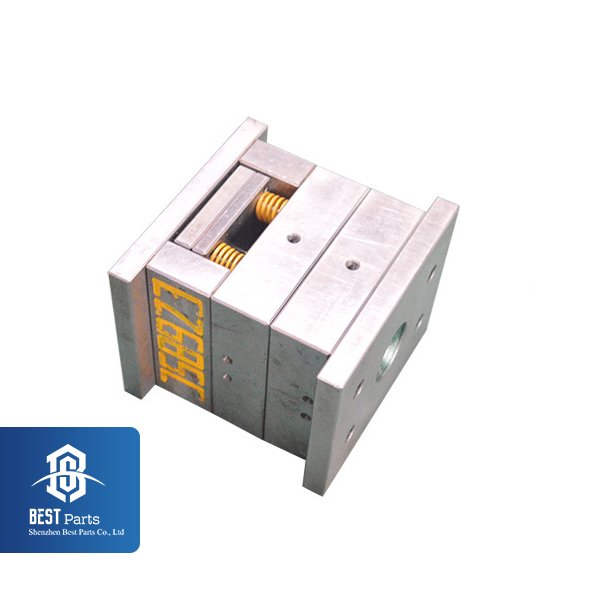

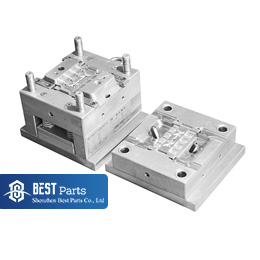

Injection Mold

What Is Injection Molding

Injection molding is the use of thermoplastics to produce large quantities of high-volume parts with complex colors, hardness and complexity. Injection molding is also used in the automotive, medical, consumer goods, electronics, packaging and other fields.

Specific products include: plastic bottles, auto parts, game products, digital products, audio, sports equipment, science and education products, instrumentation, LED lights, gifts, gears and other mold manufacturing.

Our Leading Position In The Industry

The mold development cycle is short, the precision mold is 20-35 days, and the simple mold can be completed within 20 days;Provide precision plastic and precision die-cast parts production;

Provide high-difficult, multi-process precision electronic parts assembly;

Our company has a large number of sophisticated CNC machining centers, injection molding machines, spark machines, wire cutting machines, milling machines, grinding machines, lathes, deep hole drilling, two-dimensional testing equipment and other sophisticated advanced manufacturing equipment.

Material

PVC / PC / PBT / POM / PU / ABS / PC + ABS / etc..

Packaging & Delivery

Packaging Details: Export standard package.(Carton,Wooden case,Pallet etc.) We can change some conditions according to client's request.Delivery detail: Shipped in 10~30days as according to the design&quantity.

Shipment terms: By express/air/sea, will choose the best proper logistics as per client's request.

Payment terms: By T/T, Paypal and other payment terms are acceptable.

PREVIOUS:Injection Mold

NEXT:Automotive Complex Die Cast Parts

Contact Us

Contact: Emily

Phone: +86 158 1864 3701

Tel: +86 (0755) 2377 2505

Email: emily@bestinparts.com

Add: Changshantou Industrial Park,No.149 QingZhang Road, QingXi Town,DongGuan,China 523662

lura

lura