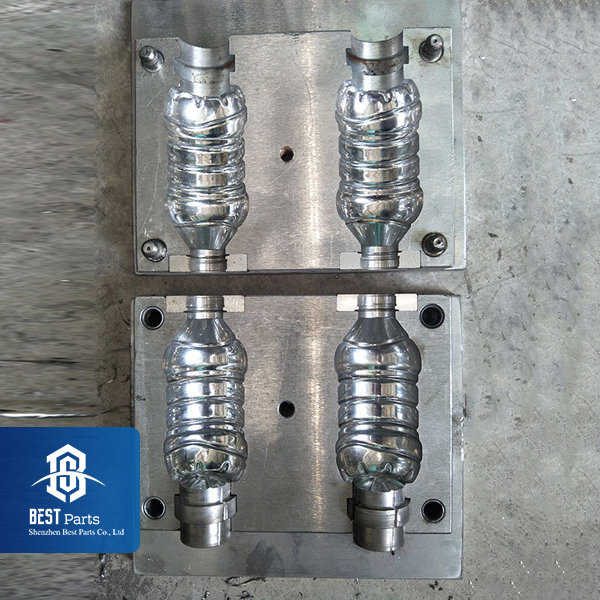

Injection Mold

Plastic Injection Molding Services

Best parts use injection molding to process complex, fine-sized plastic products. Injection molding is suitable for almost all thermoplastic products. The injection molding cycle is short, and the quality of the molded product ranges from a few grams to kilograms. After designing the mold, it can form tens of thousands of complex and accurate parts. In the mass production of customers with orders of more than 100, we will provide injection molding services to our customers.

Advantages Of Injection Molding

● Rapid production● Flexible design, such as color, transparency, strength and flexibility

● High precision

● High working efficiency

There Are Many Injection Molding Processes

● The rmoset injection molding

The rmosetting material molding requires heating or chemical methods for the crosslinked polymer chains.

● Two-color molding

Two-color molding is an injection molding process in which the molding operation of one material is performed on another material.

● Gas-assisted injection molding

At the end of the molding injection phase, an inert gas is introduced into the polymer melt under high pressure.

Why Choose BEST PARTS To Be Your Cooperative Partner

1.We have a professional work team, bring you 19+ years of mould experience!2.We always think customer first!

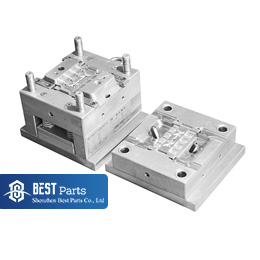

3.We have our own mold tooling workshop and specialize in OEM/ODM service!

4.We can provide one-stop service!

5.We can save your time and money!

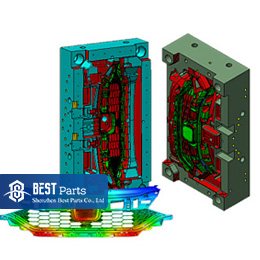

Our company adopts CNC, EDM, CNC lathe and other mold processing equipment, and has a complete production process from mold design, to injection molding, testing, packaging, transportation and other full production processes, to achieve delivery without delay and no towing process.

Our Workplace Display

Contact Us

Contact: Emily

Phone: +86 158 1864 3701

Tel: +86 (0755) 2377 2505

Email: emily@bestinparts.com

Add: Changshantou Industrial Park,No.149 QingZhang Road, QingXi Town,DongGuan,China 523662

lura

lura