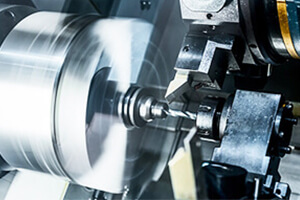

CNC Turning

CNC Turning Service

(Beat Your Deadlines With Our Quick-turn CNC Turning Parts)

| At BEST Parts ,We have high-precision machine tools and engineers with more than 20 years of experience,we are proud of the high quality of the turning parts we produce. Experienced quality personnel ensures that customer requirement are met or exceeded at all stages of production in custom industrial processing. Whether your requirements are aluminum, copper, stainless steel, polycarbonate, POM or medical plastic parts, we can help you.

|

1. BEST Parts CNC Turning Center

If you are looking for professional OEM/ODM CNC turning services or want to receive a high-quality part from a reputable and reliable supplier? 20+ Years Best Parts had provided excellent quality CNC lathe services for United States and Europe customers on demand, featuring precision machined parts, lathe parts. Our precision CNC Turning Parts applications exist in a variety of industries including automobile, electronics, medical and more. We mainly serve customers from the United States, Europe, the Middle East, and more countries & regions.

Not only can provide high-quality parts machining, Best Parts can finish excellent surface finish, especially in anodic oxidation, polishing, copper plating, etc.We have been equipped with a high precision tester, which can ensure the accuracy of the parts standard.

CNC Turning Service Reference | ||

Machining Processes | Parting/Cutting Facing ·Contour Turning ·Form Turning ·Taper Turning ·Straight Turning Threading ·External ·Internal | Internal Forming |

Material | Stainless steel: SS301,SS303,SS304,SS316F,SS316,420,etc. Steel:Carbon steel,alloy steel,4140,4340,Q235,Q345B,20#,45#,etc. Aluminium: AL6061,AL6063,AL7075,AL5052,AL6082,etc. Brass: HPb63,HPb62,HPb61,Hpb59-1,H59,H62,H68,H80,H90,etc. Copper:C11000,C12000,C36000,etc. Plastic: PVC,POM,NYLON,etc. Zinc alloy, Alumimium alloy,etc. | |

Tolerance | +/- 0.01--0.05mm / can also be customized | |

Processing equipments

| CNC machining center,NC lathe, Grinding machine, Automatic lathe machine, Conventional lathe machine,Milling machine,Drilling machine,EDM,Wire-cutting machine,CNC bending machine etc | |

Packaging | 1. inner packaging: plastic wrap, bubble bag, PE foam, EPE cotton,PP bag etc. 2. outer packaging: carton box, wooden case, plate etc. 3. as per customers' requirement | |

File Quote Type | DWG, DXF, IGES, Solid Works, Master Cam format files | |

Payment Terms | T/T, PayPal, etc | |

2. Industrial For CNC Turning Applications

The shapes that can be made by CNC turning include various flat surfaces, tapers, contours, fillet and radius contours, and threaded surfaces. Although many turned parts use a single axis of rotation, there can also be multiple axes to provide greater flexibility (for example, camshafts).

--Automotive industry: engine, housing, screws, motor shafts, bearing sleeves, knobs, gaskets, shift levers, hydraulic valves, valve housings, sensor housings

--Machinery industry: fasteners, bushings, screws (rivets, bolts, nuts), shafts, engine components

--Medical and biotechnology: medical speculums, auxiliary surgical instruments, optoelectronic instrument components

--Electronic products: PCB auxiliary board, light receiving end interface ferrule assembly, optical device metal assembly, product metal shell

If your company are preparing new projects, please contact us immediately for a free quote!

3. What Kind Of Parts Are Suitable For CNC Turning

1. Complex rotating parts. Rotating parts generally need to be rotated during terminal processing. Simple plane machining lathes cannot achieve the rotating effect.

2. For shaft parts. The following features are suitable for NC turning: parts with complex structures or shapes, common machining operations that are difficult, long working hours, and low machining efficiency. Consistency of machining accuracy requires high parts.

3.Varying cutting conditions. For example, due to the shape characteristics of the part needs to be cut, turned, threaded, etc., the cutting amount must be changed many times during processing. Each batch has a variety of parts with a certain degree of complexity.

4. For worm shaft parts with keyways, radial holes (including screw holes), and holes (including screw holes) on the end face For example, shafts with flanges, shafts with keyways or square heads can also be machined on turning centers. In addition to ordinary CNC turning, various machining surfaces such as various grooves, holes (including screw holes), and surfaces on parts can also be processed together.

4. Why Choose BEST Parts?

·Design assistance and full engineering support

·20 years' experience working with OEM's

·One stop manufacturing includes sourcing of subcomponents and hardware overseas partners

· Complete production lines for custom turning, milling, cnc machining sheet metal fabrication, stamping, bending, sliver welding and surface finish

·Advanced machine tools, CAD/CAM programming software

·Prototype machining capabilities

·Strict quality control standards with a highly qualified inspection department

·Continually upgrading and advancing our equipment to remain competitive

Categories

Contact Us

Contact: Emily

Phone: +86 158 1864 3701

Tel: +86 (0755) 2377 2505

Email: emily@bestinparts.com

Add: Changshantou Industrial Park,No.149 QingZhang Road, QingXi Town,DongGuan,China 523662

lura

lura