Injection Molding

Produce 50 to 100,000+ Finished Plastic Injection Molding Proces. To Start Your Next Project.

| At BEST Parts, we specialize in producing high-quality plastic injection molded parts and mold tools. We offer machining and finishing services to make tools from a variety of materials. With advanced material verification and quality processes, we can ensure your tools and parts exceed your expectations.

|

|

May Affect Price & Lead-Time

The time lost in plastic injection molds is probably the time it takes to make the molds. The table details the molding time of the molds.

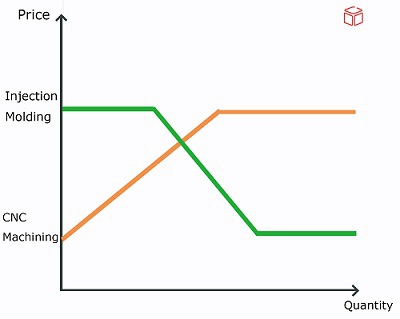

The strong economic benefit of injection molds is that as long as the initial cost of mold manufacturing is paid, the price per unit during injection molding will be very low.Upload your product design information for a competitive injection molding quote today.

Tool Options | Lead-Time and another elements |

Rapid Tool (Master Unit Die Base) | Lead Time:1-3 weeks ( Depends On Size and Complexity) Part Quantity: 5000 Tool Tolerances:±0.003 + 0.002in/in Finish (Texture):contain |

Prototype Tool(Stand Alone) | Lead Time:2-4 weeks ( Depends On Size and Complexity) Part Quantity: 5000-50000 Tool Tolerances:±0.005 +0.002in/in Finish (Texture):contain |

|

|

BEST Parts & Injection Molding Application

Injection molding is widely used in products for various occasions. If you look around your desk, you will find many injection molded products, including remote control housings, console covers, storage boxes and most plastic products.

Injection molding is also used in the following occasions:

● Medical

● aerospace

● Automobile industry

● electronic product

● industry

Injection products for metering equipment

Injection Molding Process

The process of the injection molding process includes: clamping, injection molding, dwelling, cooling the mold, opening, and obtaining the product. Every process must guarantee the correct temperature and processing materials.

Why use injection molding

The main advantage of injection molding is the ability to produce on a large scale. After paying for the mold and designing the original, the price per unit during the injection molding process is very low. Other advantages :

● Reduce waste

● Easy to repeat process

● High productivity

● Multiple available materials

● Low labor costs

If you want to start a business with injection molding, you may need to know some basic information: |

Initial cost: Preparing a product for injection molding requires a certain amount of cost. Production quantity : BEST PARTS can produce small and large quantities of parts, and it is necessary to determine injection molding as the most cost-effective manufacturing method. Delivery time : Mold design takes time and is just one step in injection molding. Before the production of injection molded parts, the parts must be designed for prototyping (possibly by CNC or 3D printing) before the parts can be mass-produced. Finally, you usually get injection molded parts after extensive testing in both stages. |

If you would like more information, please pay attention to our other injection molding process. If you are looking for an injection molding service, please send us your request.

CLICK BELOW TO START A QUOTE WITH |

BEST Parts Injection Molding Shop

EDM Work Shop and CNC Machining Work Shop

CNC Machining Work Shop

Categories

Contact Us

Contact: Emily

Phone: +86 158 1864 3701

Tel: +86 (0755) 2377 2505

Email: emily@bestinparts.com

Add: Changshantou Industrial Park,No.149 QingZhang Road, QingXi Town,DongGuan,China 523662

lura

lura